We offer our customer the biggest modern Furnace in Europa because…

we can „big and heavy“

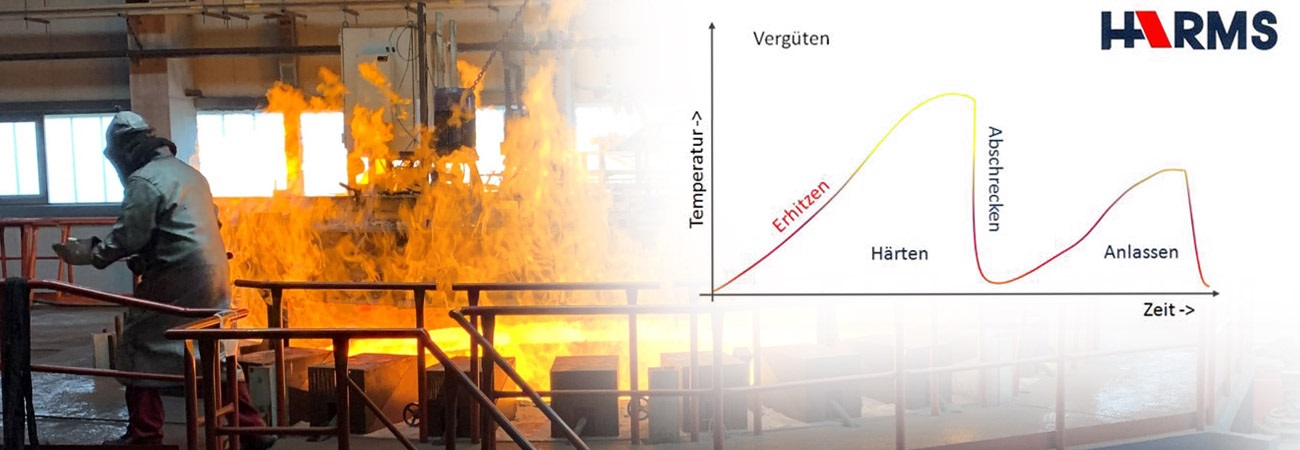

Tempering of drop forgings

Tempering is understood to mean hardening with subsequent tempering to temperatures of approx. 550 to 650 ̊ C. The microstructural changes occurring in the material result in a significant increase in toughness in addition to high strength.

echnical parameters:

-

Individual remuneration

-

Forgings up to 80 kg

-

Throughput 800 kg / h

500 to / Mon -

oil-based remuneration

-

all annealing processes possible

(Normalize,and stress relief heat Treatment)

Typical parts:

-

steering knuckle

-

Crankshafts

-

crown wheels

-

Clutch Discs

-

Drive wheels

Harms Lohnhärterei GmbH & Co.KG

Harms Vergüterei GmbH & Co.KG

Salbker Str. 23 / 23a

39120 Magdeburg