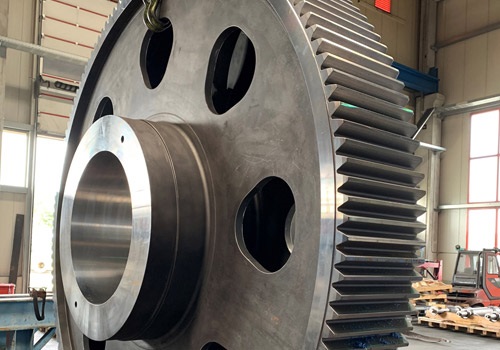

Topic: "Theoretical and practical studies on the first case hardening of oversized components, especially of gear wheels, as well as the development of a corresponding simulation model."

The Harms contract hardening shop carried out the most extensive research project in its young company history together with several institutes of the Otto von Guericke University Magdeburg and with competent partners in mechanical engineering. In the tradition of decades of fruitful cooperation between Magdeburg's mechanical engineering and the former "Technical University for Heavy Engineering", we have the opportunity, funded by the Federal Ministry of Economics and Technology, to carry out comprehensive studies to ensure quality and to further develop the case hardening of large components in an innovative way. The main contents of the research project are:

The development of operational simulation models for the characterization of the thermal behavior of thick-walled components as well

Extensive practical and laboratory tests to prove the technological parameters achieved in the large carburizing plant, e.g. Case hardness depth, carbon content, mechanical parameters.

With the solution of these tasks, we want to contribute to realizing the case hardening of very large transmission components as a more advantageous alternative to other processes on a scientifically and technically sound basis and with reproducible quality and thus to do justice to future development trends and innovations in mechanical engineering.

We are always available for a free consultation.

Give us a call: +49 391/6 11 37 - 0 Fax : +49 391/6 21 97 14

phone +49391/6 11 37